Phone-Controlled Robotic Arm

This robotic arm has the ability to flex and grab objects around it using the help of the servos at each of its joints. You can control the arm in two ways: the 2-joystick controller or on an app on your phone. While the installation and software process encountered some bumps along the road, I am still very proud of the overall end product and its functionality!

| Engineer | School | Area of Interest | Grade |

|---|---|---|---|

| Samhita V | Mountain View High School | CS/AI | Incoming Junior |

Modification Milestone

Description

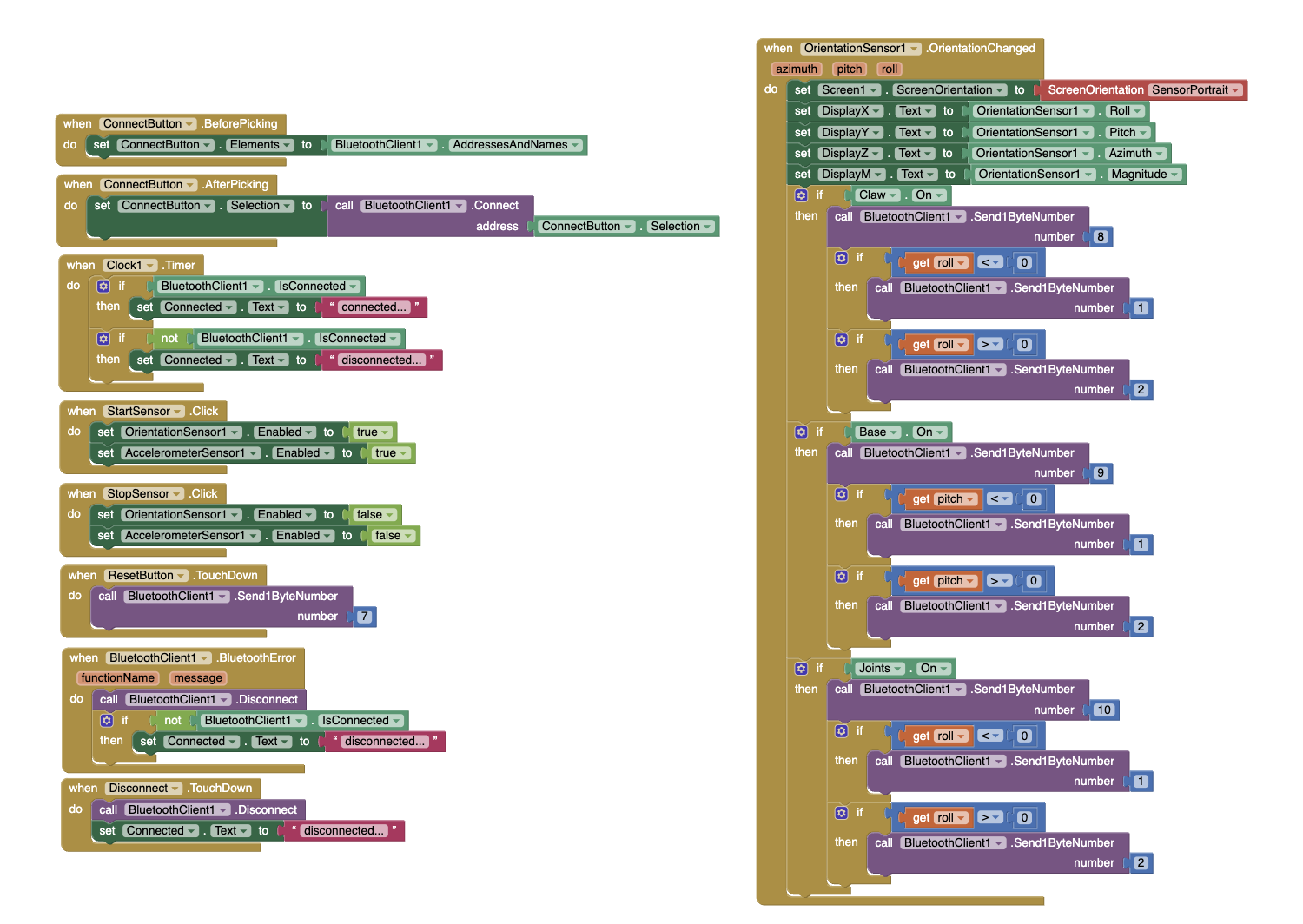

This Android app for the robotic arm uses a switch system and an orientation sensor to control the arm based on the physical movement of the phone. When a switch for a particular servo/point of movement is enabled, a number is returned and sent to the Bluetooth module, which is then read by the code. Based on the number read, the code will tell the arm which servo will be receiving instructions for movement, and also how to move the servo based on the phone’s tilt/angle. The bluetooth module facilitates this connection between the phone and the Arduino and allows for the code to be read from both ends.

Challenges

There were a significant amount of challenges during this process. I created and tested two different interfaces with different coding approaches before I was able to find something that worked with the arm. For example, in the beginning, there were no switches made and I expected all the servos to run at once while the phone is moving. This caused an overload in data and caused the arm to have jittery movements that burned out the power in the batteries. To solve this, I used switches to have precise movements that the user can predict and control. There was also a debate between whether or not I should use an orientation sensor over an accelerometer. Eventually, I weighed the pros and cons based on my needs and settled on the orientation sensor, which would give my code the data it needs to fully control the arm. Eventually, I was able to get the app working and now it works and pairs smoothly with the robotic arm.

Next Steps

My next steps are to practice my presentation for Demo Night.

Mod Arm App Block Code

Second Block Code Iteration Figure #1

Second Block Code Iteration Figure #1

Mod Arm App Arduino Code

#include "CokoinoArm.h"

#include <NeoSWSerial.h>

#define buzzerPin 9

int screen, state, move, move2, move3;

CokoinoArm arm;

int xL,yL,xR,yR;

NeoSWSerial BTSerial(3,2);

const int act_max=10; //Default 10 action,4 the Angle of servo

int act[act_max][4]; //Only can change the number of action

int dataIn[2];

int num=0,num_do=0;

void turnUD(void){

if(xL!=512){

if(0<=xL && xL<=100){arm.up(10);return;}

if(900<xL && xL<=1024){arm.down(10);return;}

if(100<xL && xL<=200){arm.up(20);return;}

if(800<xL && xL<=900){arm.down(20);return;}

if(200<xL && xL<=300){arm.up(25);return;}

if(700<xL && xL<=800){arm.down(25);return;}

if(300<xL && xL<=400){arm.up(30);return;}

if(600<xL && xL<=700){arm.down(30);return;}

if(400<xL && xL<=480){arm.up(35);return;}

if(540<xL && xL<=600){arm.down(35);return;}

}

}

void turnLR(void){

if(yL!=512){

if(0<=yL && yL<=100){arm.right(0);return;}

if(900<yL && yL<=1024){arm.left(0);return;}

if(100<yL && yL<=200){arm.right(5);return;}

if(800<yL && yL<=900){arm.left(5);return;}

if(200<yL && yL<=300){arm.right(10);return;}

if(700<yL && yL<=800){arm.left(10);return;}

if(300<yL && yL<=400){arm.right(15);return;}

if(600<yL && yL<=700){arm.left(15);return;}

if(400<yL && yL<=480){arm.right(20);return;}

if(540<yL && yL<=600){arm.left(20);return;}

}

}

void turnCO(void){

if(arm.servo4.read()>7){

if(0<=xR && xR<=100){arm.close(0);return;}

if(900<xR && xR<=1024){arm.open(0);return;}

if(100<xR && xR<=200){arm.close(5);return;}

if(800<xR && xR<=900){arm.open(5);return;}

if(200<xR && xR<=300){arm.close(10);return;}

if(700<xR && xR<=800){arm.open(10);return;}

if(300<xR && xR<=400){arm.close(15);return;}

if(600<xR && xR<=700){arm.open(15);return;}

if(400<xR && xR<=480){arm.close(20);return;}

if(540<xR && xR<=600){arm.open(20);return;}

}

else{arm.servo4.write(8);

}

}

void date_processing(int *x,int *y){

if(abs(512-*x)>abs(512-*y))

{*y = 512;}

else

{*x = 512;}

}

void buzzer(int H,int L){

while(yR<420){

digitalWrite(buzzerPin,HIGH);

delayMicroseconds(H);

digitalWrite(buzzerPin,LOW);

delayMicroseconds(L);

yR = arm.JoyStickR.read_y();

}

while(yR>600){

digitalWrite(buzzerPin,HIGH);

delayMicroseconds(H);

digitalWrite(buzzerPin,LOW);

delayMicroseconds(L);

yR = arm.JoyStickR.read_y();

}

}

void C_action(void){

if(yR>800){

int *p;

p=arm.captureAction();

for(char i=0;i<4;i++){

act[num][i]=*p;

p=p+1;

}

num++;

num_do=num;

if(num>=act_max){

num=0;

buzzer(600,400);

}

while(yR>600){yR = arm.JoyStickR.read_y();}

//Serial.println(act[0][0]);

}

}

void Do_action(void){

if(yR<220) {

buzzer(200,300);

for(int i=0;i<num_do;i++) {

arm.do_action(act[i],15);

}

num=0;

while (yR<420) {

yR = arm.JoyStickR.read_y();

}

for(int i=0;i<2000;i++){

digitalWrite(buzzerPin,HIGH);

delayMicroseconds(200);

digitalWrite(buzzerPin,LOW);

delayMicroseconds(300);

}

}

}

void setup() {

Serial.begin(9600);

BTSerial.begin(9600);

//arm of servo motor connection pins

arm.ServoAttach(5,11,7,10);

//arm of joy stick connection pins : xL,yL,xR,yR

arm.JoyStickAttach(A0,A1,A2,A3);

pinMode(buzzerPin,OUTPUT);

arm.servo1.write(90);

arm.servo2.write(90);

arm.servo3.write(90);

arm.servo4.write(120);

}

int val, cnt = 0;

int v[2];

void readBT() {

val = BTSerial.read();

cnt++;

v[cnt] = val;

if (cnt == 2) {

cnt = 0;

}

}

int in_byte, array_index;

void loop() {

if (BTSerial.available() > 1) { //recieve byte from phone

in_byte = BTSerial.read(); //store in byte into a variable

//Serial.println(in_byte);

if (in_byte == 0) { // if the variable is 0 stet the array inxed to 0. this will make sure that every number goes into the correct index

array_index = 0;

}

if (in_byte == 7 || in_byte == 8 || in_byte == 9 || in_byte == 10) {

array_index = 1;

state = in_byte;

move = BTSerial.read();

Serial.println(state);

} else {

array_index = 2;

}

dataIn[array_index] = in_byte; //store number into array

//Serial.println(dataIn[2]);

//state = dataIn[1];

//array_index = array_index +1;

}

if (state == 8) {

//move = dataIn[2];

arm.servo1.write(90);

arm.servo2.write(90);

arm.servo3.write(90);

//dataIn[1] = move;

//Serial.println(move);

if(move == 1) {

arm.open(20);

}

if(move == 2) {

arm.close(20);

}

}

if (state == 9) {

//move2 = dataIn[2];

arm.servo2.write(90);

arm.servo3.write(90);

arm.servo4.write(120);

if(move == 1) {

arm.left(20);

}

if(move == 2) {

arm.right(20);

}

}

if (state == 10) {

//move3 = dataIn[2];

arm.servo1.write(90);

//arm.servo4.write(90);

if(move == 1) {

arm.down(20);//moves arm up just says down

}

if(move == 2) {

arm.up(20);//moves arm down just says up

}

}

if(state == 7) {

arm.servo1.write(90);

arm.servo2.write(90);

arm.servo3.write(90);

arm.servo4.write(120);

}

if(arm.servo4.read() < 7) {

arm.servo4.write(8);

}

//Serial.println(state);

}

Final Milestone

Description

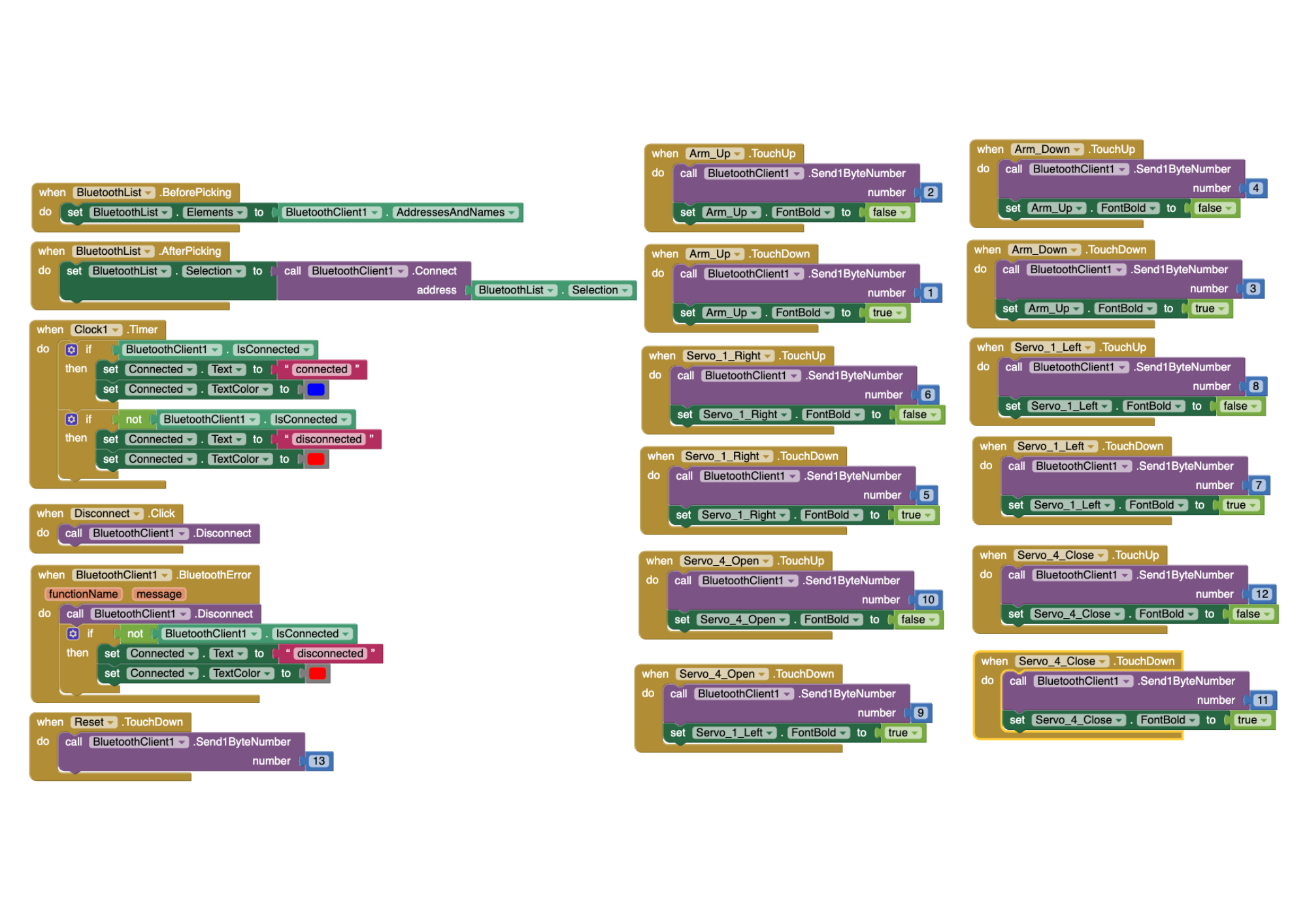

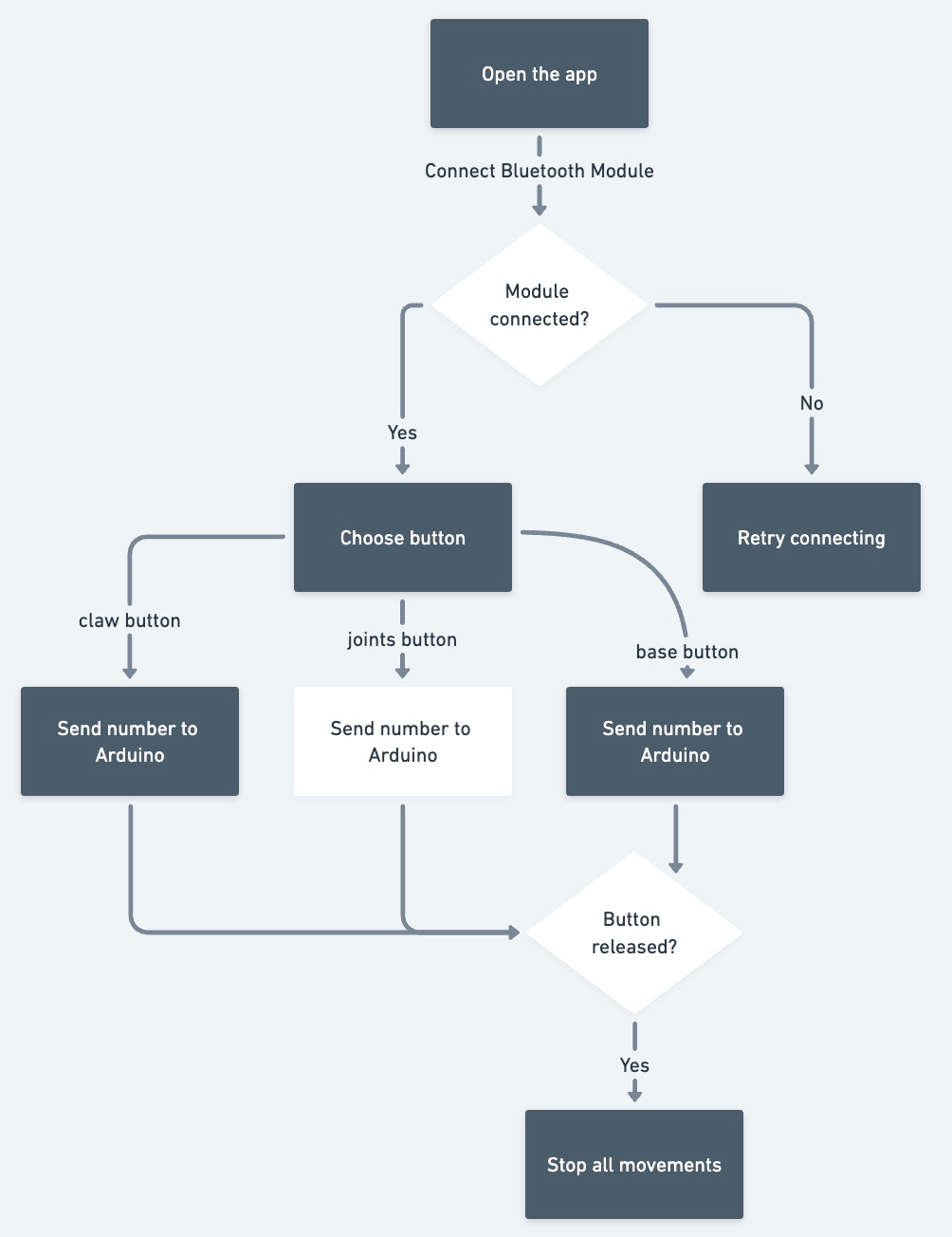

This Android app for the robotic arm consists of a two-way button interface that controls 3 points of movement on the arm (the base, the joints, and the claw) and also has a reset button that reconfigures all servos to its base rotation point of 90 degrees. On the MIT App Interface, I was able to set and configure different buttons to control and maintain points of movement on the arm to make it more user friendly. For the block code, I made it so that when a button is pressed for a certain servo movement type, a number is returned. In the Arduino code, I made sure to configure the precise movements of the servos based on whatever number was outputted so that the Arduino could understand how to move the servo based on outputs from the phone. The bluetooth module facilitates this connection between the phone and the Arduino and allows for the code to be read from both ends.

Challenges

There were many challenges during this process. I created and tested 4 different app interfaces with 4 different types of code before I was able to settle on something that was compatible with the arm. For example, one of my earlier interfaces used sliders instead of buttons, however, using the sliders was relatively harder for the arm to read and wasn’t able to precisely control the movements therefore wasting power in the process. Because of this, the app would freeze up, shut down, or cause the bluetooth module to disconnect frequently causing multiple errors. To solve this, I switched to using buttons in the new interface, as well as combining the points of movement from 4 to 3 to make it simpler to move. I also switched out the batteries since the earlier interfaces were draining its voltage. Eventually, I was able to get the app working and now it pairs smoothly with the robotic arm.

Next Steps

My next steps are to research and start working on my modifications.

Arm App Block Code

First Block Code Iteration Figure #2

First Block Code Iteration Figure #2

Arm App Arduino Code

#include "CokoinoArm.h"

#include <SoftwareSerial.h>

#define buzzerPin 9

int state=0;

CokoinoArm arm;

int xL,yL,xR,yR;

SoftwareSerial BTSerial(3,2);

const int act_max=10; //Default 10 action,4 the Angle of servo

int act[act_max][4]; //Only can change the number of action

int num=0,num_do=0;

void turnUD(void){

if(xL!=512){

if(0<=xL && xL<=100){arm.up(10);return;}

if(900<xL && xL<=1024){arm.down(10);return;}

if(100<xL && xL<=200){arm.up(20);return;}

if(800<xL && xL<=900){arm.down(20);return;}

if(200<xL && xL<=300){arm.up(25);return;}

if(700<xL && xL<=800){arm.down(25);return;}

if(300<xL && xL<=400){arm.up(30);return;}

if(600<xL && xL<=700){arm.down(30);return;}

if(400<xL && xL<=480){arm.up(35);return;}

if(540<xL && xL<=600){arm.down(35);return;}

}

}

void turnLR(void){

if(yL!=512){

if(0<=yL && yL<=100){arm.right(0);return;}

if(900<yL && yL<=1024){arm.left(0);return;}

if(100<yL && yL<=200){arm.right(5);return;}

if(800<yL && yL<=900){arm.left(5);return;}

if(200<yL && yL<=300){arm.right(10);return;}

if(700<yL && yL<=800){arm.left(10);return;}

if(300<yL && yL<=400){arm.right(15);return;}

if(600<yL && yL<=700){arm.left(15);return;}

if(400<yL && yL<=480){arm.right(20);return;}

if(540<yL && yL<=600){arm.left(20);return;}

}

}

void turnCO(void){

if(arm.servo4.read()>7){

if(0<=xR && xR<=100){arm.close(0);return;}

if(900<xR && xR<=1024){arm.open(0);return;}

if(100<xR && xR<=200){arm.close(5);return;}

if(800<xR && xR<=900){arm.open(5);return;}

if(200<xR && xR<=300){arm.close(10);return;}

if(700<xR && xR<=800){arm.open(10);return;}

if(300<xR && xR<=400){arm.close(15);return;}

if(600<xR && xR<=700){arm.open(15);return;}

if(400<xR && xR<=480){arm.close(20);return;}

if(540<xR && xR<=600){arm.open(20);return;}

}

else{arm.servo4.write(8);

}

}

void date_processing(int *x,int *y){

if(abs(512-*x)>abs(512-*y))

{*y = 512;}

else

{*x = 512;}

}

void buzzer(int H,int L){

while(yR<420){

digitalWrite(buzzerPin,HIGH);

delayMicroseconds(H);

digitalWrite(buzzerPin,LOW);

delayMicroseconds(L);

yR = arm.JoyStickR.read_y();

}

while(yR>600){

digitalWrite(buzzerPin,HIGH);

delayMicroseconds(H);

digitalWrite(buzzerPin,LOW);

delayMicroseconds(L);

yR = arm.JoyStickR.read_y();

}

}

void C_action(void){

if(yR>800){

int *p;

p=arm.captureAction();

for(char i=0;i<4;i++){

act[num][i]=*p;

p=p+1;

}

num++;

num_do=num;

if(num>=act_max){

num=0;

buzzer(600,400);

}

while(yR>600){yR = arm.JoyStickR.read_y();}

//Serial.println(act[0][0]);

}

}

void Do_action(void){

if(yR<220){

buzzer(200,300);

for(int i=0;i<num_do;i++){

arm.do_action(act[i],15);

}

num=0;

while(yR<420){yR = arm.JoyStickR.read_y();}

for(int i=0;i<2000;i++){

digitalWrite(buzzerPin,HIGH);

delayMicroseconds(200);

digitalWrite(buzzerPin,LOW);

delayMicroseconds(300);

}

}

}

void setup() {

Serial.begin(9600);

BTSerial.begin(9600);

//arm of servo motor connection pins

arm.ServoAttach(5,11,7,10);

//arm of joy stick connection pins : xL,yL,xR,yR

arm.JoyStickAttach(A0,A1,A2,A3);

pinMode(buzzerPin,OUTPUT);

arm.servo1.write(90);

arm.servo2.write(90);

arm.servo3.write(90);

arm.servo4.write(90);

}

void loop() {

if(BTSerial.available()>0){

state=BTSerial.read();

}

if(state==1){

arm.down(20);//moves arm up just says down

}

if(state==3){

arm.up(20);//moves arm down just says up

}

if(state==5){

arm.left(20);

}

if(state==7){

arm.right(20);

}

if(state==9){

arm.open(20);

}

if(state==11){

arm.close(20);

}

if(state==13){

arm.servo1.write(90);

arm.servo2.write(90);

arm.servo3.write(90);

arm.servo4.write(90);

}

if(arm.servo4.read()<7){

arm.servo4.write(8);

}

Serial.println(state);

xL = arm.JoyStickL.read_x();

yL = arm.JoyStickL.read_y();

xR = arm.JoyStickR.read_x();

yR = arm.JoyStickR.read_y();

date_processing(&xL,&yL);

date_processing(&xR,&yR);

turnUD();

turnLR();

turnCO();

C_action();

Do_action();

}

Arm App Code Flowchart

Flowchart Figure #3

Flowchart Figure #3

Second Milestone

Description

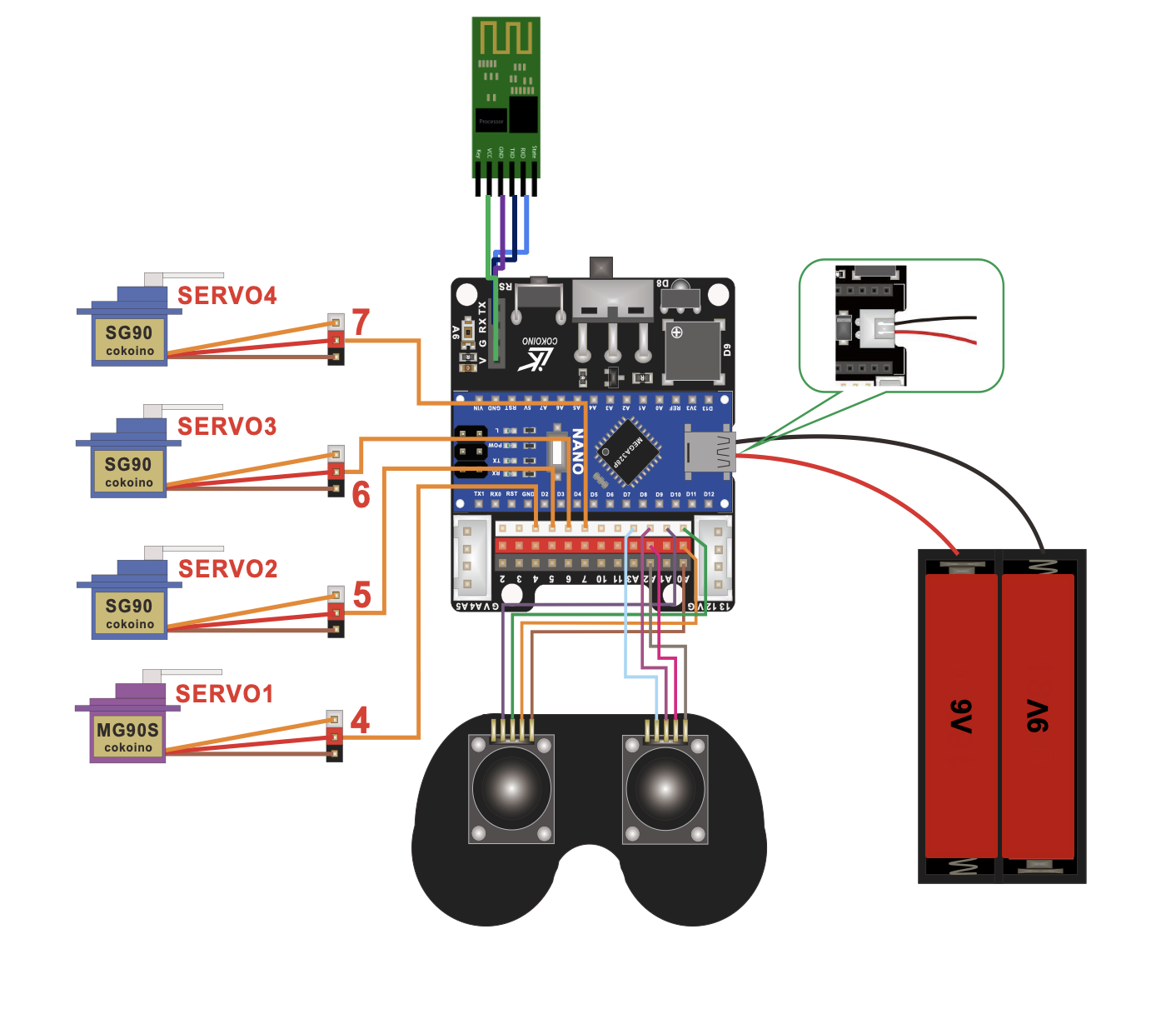

For my main project, my second milestone was to program the joystick controller to be compatible with my robotic arm. Using code functions from the Servo library, the controller is able to manipulate the movement of the servos positions and set it to a specific rotation point based on how much the joystick is pushed forward/backwards. The servo wires that are connected to the Arduino help the computer read which servo should be moved according to which joystick is moved. The battery ensures that enough voltage is moving through the entire circuit so the robotic arm has enough energy to move freely without having jittery movements.

Challenges

There were a significant amount of challenges during this process, including issues in the electrical, mechnical, software, and power areas. When the provided code was uploaded, the robotic arm would go haywire and move entirely on its own without any prompting from the controller. We hoped that this meant it was a software issue, and rewrote the code from scratch to have a simpler way to control the arm. However, when that wasn’t enough, we tried to isolate the movement of each individual servo to check if there were any faulty or broken ones that were attached. We found that servo 2 was broken, and replaced it with another servo, yet that one was also considerably weak and could not support the weight of the upper arm, and ended up replacing it a second time before it finally worked. There were also issues with loose jumper wires, which meant replacing and reiterating the wiring for both the servos and the joycon. There was also issues with the battery pack, due to it being plugged in for extensive periods of time, the voltage considerably lowered and became very weak, which meant replacing the batteries as well and being mindul of how long it is being used. While there were issues in each of these categories, eventually I was able to power through these challenges and create a working controller for my robotic arm.

Next Steps

My next steps are to code the app which will also be able to control the robotic arm.

Joycon Code

#include <Servo.h>

Servo servo1;

Servo servo2;

Servo servo3;

Servo servo4;

int servoAng1, servoAng2, servoAng3, servoAng4;

void setup () {

Serial.begin(9600);

servo1.attach(5); //Set the servo control pin as D4

servo2.attach(6); //Set the servo control pin as D5

servo3.attach(7); //Set the servo control pin as D6

servo4.attach(10); //Set the servo control pin as D7

}

int data_processing(int x) {

if (x < 0) {

x = 0;

}

if (x > 180) {

x = 180;

}

return x;

}

int joystick (int reading) {

reading = (reading / 100) - 5;

if (reading > -2 && reading < 0) {

reading = 0;

}

return reading;

}

void loop () {

int xL = joystick(analogRead(A0));

int yL = joystick(analogRead(A1));

int xR = joystick(analogRead(A2));

int yR = joystick(analogRead(A3));

servoAng1 += xL;

servoAng2 += yL;

servoAng3 += xR;

servoAng4 += yR;

servo1.write(servoAng1);

servo2.write(servoAng2);

servo3.write(servoAng3);

servo4.write(servoAng4);

servoAng1 = data_processing(servoAng1);

Serial.println(servo1.read());

servoAng2 = data_processing(servoAng2);

Serial.println(servo2.read());

servoAng3 = data_processing(servoAng3);

Serial.println(servo3.read());

servoAng4 = data_processing(servoAng4);

Serial.println(servo4.read());

delay(50);

}

First Milestone

Description

For my main project, my first milestone was to assemble and build the components of my robotic arm, which includes the structure of the arm itself and the 2-joystick controller. I chose this project primarily because of its significance and symbolism of the many advancements in the robotics field and its usefulness in medical areas. These inventions have been influential to so many people and I wanted to experience what it would be like to create a simpler version of a prosthetic arm. This project is also the perfect difficulty level as it is not too hard but enough to challenge me in the right areas and expand my skill set. There are three main components to this project: the battery pack, the Arduino Nano board, and the structure of the arm itself. The battery pack is used to power the arm since it cannot function from the power provided by the computer alone. The Arduino Nano board is what facilitates communication between the computer and the arm + controller, which is how the arm is able to read code and able to move specific joints based on commands from the controller. The robotic arm has 4 main points of movement: the turning table on the bottom, the two joints on the arm, and the opening/closing of the claw at the top.

Challenges

Some challenges I had was finding and alternate design solution for my battery pack, since it was much wider than the one initally provided so I would not be able to screw it in the traditional way. Instead, we decided to use velcro tape to stick the battery pack onto the edge of the base plate. Another challenge I faced was installing the servo bracket onto the MG90 servo, since I made the mistake of installing it last which caused problems due to the limited space for my screwdriver to secure the bracket in place. However, after much struggle, I was able to fix it in place and it is able to work and function smoothly.

Next Steps

My next steps from here are to code the controller to be able to move certain joints depending on the movement and direction of the individual joystick.

Schematics

Schematics drawn by Cokoino

Servo/Joycon Wiring Diagram Figure #4

Bill of Materials

| Part | Note | Price | Link |

|---|---|---|---|

| Arduino Nano | Managing and controlling the robot’s components | $24.90 | Link |

| Bluetooth Module | Sending and processing signals between the app and the Arduinor | $7.99 | Link |

| SG90 Servos | Moving the joints and wooden components | $16.95 | Link |

| MG90 Servo | Moving the base | $10.99 | Link |

| Batteries | Powering the Arduino and Bluetooth Module | $6.58 | Link |

| JST Battery Connectors | Connect the batteries to the circuit’s battery pin | $8.99 | Link |

| Battery Clips | Hold the batteries to flow its current into the JST connectors | $5.99 | Link |

| Female to Female Connectors | Connecting the Arduino to the wired controller | $6.98 | Link |

| Joysticks | Allow the user to control the robot using a controller | $9.95 | Link |

Starter Milestone

Description

For my starter project, I chose the BlueStamp Arduino Starter. I have had prior experiences with Arduinos in CS classes I have taken at school, but those have been very software heavy, rather than mechanical or electrical heavy. By choosing this starter, I hoped to gain more knowledge on circuits and Arduinos as a whole since my final project uses them as well, and it would be productive to get familiar with how to build and manage Arduino boards. The board has an input, the button, and an output, the LED. When the button is pressed, a message (taken from the code) is transferred throughout the jumper wires and to the Arduino, which is then passed on to the LED which tells it to turn on, until the button is released which severs the connection. The voltage transmission is regulated and controlled by the resistor which is able to limit the voltage being passed throughout the circuit so it is not too little or too much.

Challenges

Some challenges I faced was mounting the proto-sheild onto the Arduino board since the intructions were a bit complicated, and having to solder the two boards together was also a challenge due to the limited space and my limited skill set with soldering. There were also some struggles with the circuit connection between the button and LED. However, after going through each step carefully and thoroughly, I was able to pinpoint the exact problem and where it was coming from, and then able to solve any issues I had.

Next Steps

Now that this project is completed, and I have a better understanding of Arduino boards and circuits, I can now start on my final project!